Revolutionizing Manufacturing with Digital Twins for Next-Gen Innovation

- Sohel Hussain

- Oct 13, 2025

- 4 min read

Digital twins are revolutionizing the manufacturing world, and this video aims to explain the concept simply, guide viewers through how digital twins work, and illustrate why they matter with practical examples.

What Is a Digital Twin?

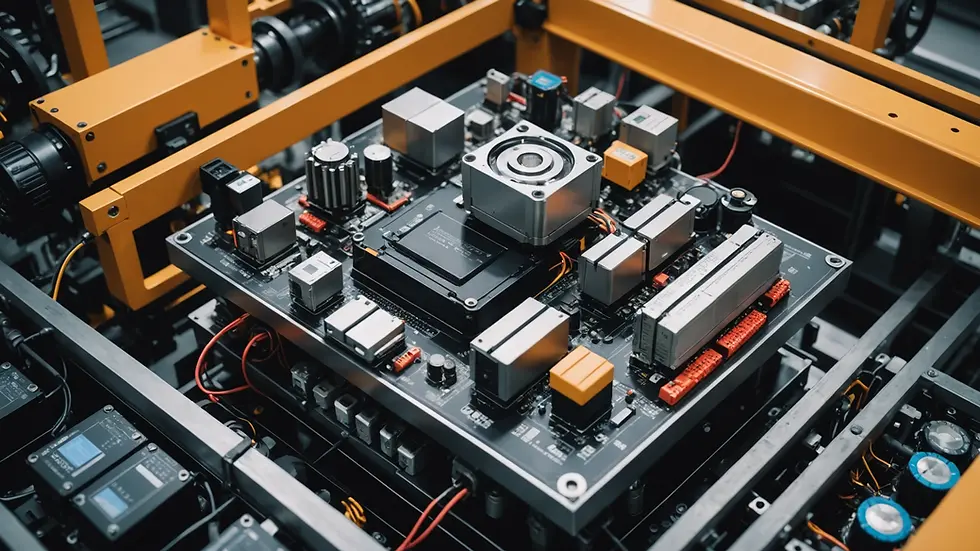

To start, a digital twin is a virtual replica of something physical—an asset, a machine, or even an entire factory. Imagine that everything happening on your shop floor is mirrored in a dynamic, interactive computer model, updating in real time thanks to sensors and data inputs. This isn’t just a digital image or a static schematic; it’s a living, breathing digital version that reflects actual conditions and behaviors, constantly evolving as the real-world counterpart changes. Watch on youtube How Digital Twins Work in Manufacturing

Take a typical scenario in manufacturing. Suppose you manage a fleet of CNC machines. Each machine is equipped with sensors monitoring vibration, temperature, and energy use. The digital twin collects all this data, building a model that matches what’s happening on the factory floor.

This setup allows operators to:

Check machine status remotely,

Simulate maintenance before doing repairs,

And predict possible failures—all from their dashboards.

If the system picks up an anomaly, such as extra heat on one spindle, the digital twin not only signals the impending issue but can simulate various maintenance options, helping choose the least disruptive and most effective fix, and even updating the simulation as the fix is applied.

A Brief History of Digital Twins

The history of digital twins dates back to the early 2000s, when manufacturers used simple computer models for product lifecycle management. With the rise of Industry 4.0—marked by the integration of automation, data exchange, IoT sensors, and artificial intelligence—the capabilities of digital twins have exploded.

Today, entire factories—or global supply chains—can be mirrored digitally, enabling organizations to keep a virtual finger on every pulse in their operations.

Steps to Implement a Digital Twin

Implementing a digital twin requires a few deliberate steps:

Identify key assets or processes that will benefit most—usually components that are critical, costly to maintain, or prone to breakdown.

Create the digital representation, using engineering blueprints, CAD models, or manually built designs as the foundation.

Integrate sensors with these assets to transmit real-time operational data to the digital model.

Leverage AI and big data analytics to power the twin, drawing insights from every data stream continuously. Watch on youtube

The Major Benefits of Digital Twins

The benefits are substantial:

Real-time monitoring and remote visualization: A maintenance supervisor can log in and instantly see not only current equipment status but also historical performance—super valuable for tracking wear and predicting when to service.

Predictive maintenance: Eliminates unplanned downtime and reduces costs because repairs and tweaks are performed only when truly necessary.

Virtual simulations: Engineers can simulate new processes, like changing a temperature profile, to determine outcomes without touching the actual machine—avoiding waste and costly errors.

Accelerating Product Development and Supply Chains

Product development accelerates as well. Before building a new part, engineers can run virtual tests using the digital twin, iterating designs and validating performance under different conditions.

Supply chains are transformed, too: with digital twins, manufacturers visualize the journey of raw materials and finished goods in real time, optimizing logistics and inventory at every step.

Real-World Examples of Digital Twin Applications

Examples help clarify how deeply digital twins can change day-to-day manufacturing:

At a global automotive plant, managers start the day by reviewing digital twins of every robot and conveyor.

A vibration anomaly popped up in the digital twin for a robot arm, and the system flagged it before a breakdown occurred—allowing preventative maintenance and keeping production on track.

During a ramp-up for a new product, engineers used digital twins to model the impact of adding extra shifts and tuning machine settings, finding the best choice for quality and speed—all virtually, with zero disruption.

In renewable energy factories, companies like Siemens Gamesa use digital twins to monitor wind turbine blade production, minimizing scrap, maximizing uptime, and continuously sharpening sustainability.

The Technology Behind Digital Twins

The technology relies on powerful enablers. The backbone of digital twins is the sensor-rich Internet of Things (IoT)—tiny devices delivering streams of data to the digital model.

Artificial Intelligence (AI) and Machine Learning (ML) analyze these inputs, uncovering patterns and predicting future behaviors.

Virtual Reality (VR) and Augmented Reality (AR) take things even further, allowing users to interact with the digital twin as if they’re “inside” the factory, exploring scenarios and making decisions intuitively.

Conclusion: Why Digital Twins Are a Game-Changer

In summary, digital twins in manufacturing are dynamic digital replicas of real factories, machines, and processes. They provide instant insights, deliver predictive capabilities, and empower smarter decision-making, ensuring efficiency, quality, and innovation.

Whether you want to cut costs, prevent downtime, speed up product development, or make your operations more sustainable, digital twins are a game-changer.

This video is your guide to understanding and implementing digital twins—turning your shop floor into a high-tech, efficient powerhouse designed for today and the future. How Avizops Is Revolutionizing the Industry with Digital Twin Technology

Avizops is at the forefront of making industries future-ready by integrating Digital Twin Technology with AI-driven analytics and real-time quality intelligence. By bridging the gap between physical production lines and digital intelligence, Avizops enables manufacturers to visualize their entire plant ecosystem, simulate improvements, and make proactive decisions before problems arise. Avizops isn’t just adopting digital twins; it’s redefining how factories operate — building a connected, intelligent, and sustainable future for global manufacturing. Watch on youtube

Comments